NASA Life Code

2500.00 €

+ VAT

NASA Life Code is an advanced tool for determining the life cycles of machine components based on a stress criterion. We developed this tool based on MansonMcKnight method described in “NASALIFE-Component Fatigue and Creep Life Prediction Program”.

With this solution, you have a reliable tool that is fully integrated into Ansys Workbench environment, gives reliable results, and has an intuitive user interface not found in other software of this type.

NASA Life Code is a tool for determining the life of machine components based on the stress approach contained in NASALIFE document. The plug-in clearly and transparently guides the engineer through the process of fatigue cycle calculation. Results are presented directly on the model as well as in tabular form in a user-friendly GUI.

The tool has implemented two main methods presented in the document “NASALIFE-Component Fatigue and Creep Life Prediction Program” namely:

- MansonMcKnight ;

- modified MansonMcKnight.

The tool is equipped with functions such as:

- cycle counting based on rainflow method;

- damage rainflow.

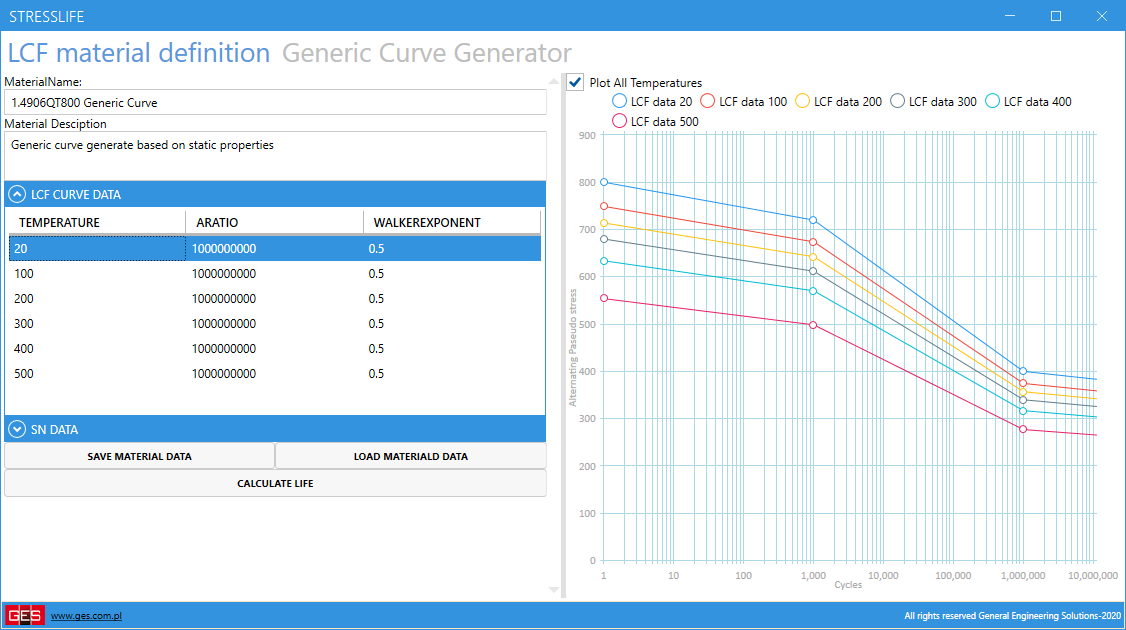

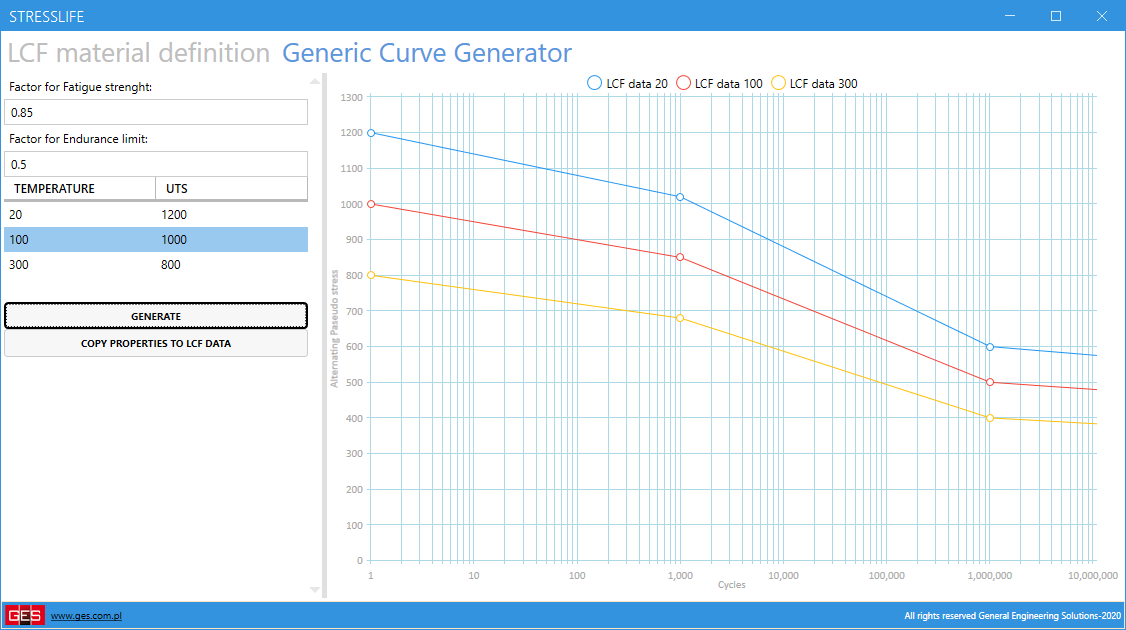

The tool has a graphical user interface (GUI) for entering material data with the ability to read and write from a file. If no data is available, curves can be generated based on the static properties of the material.

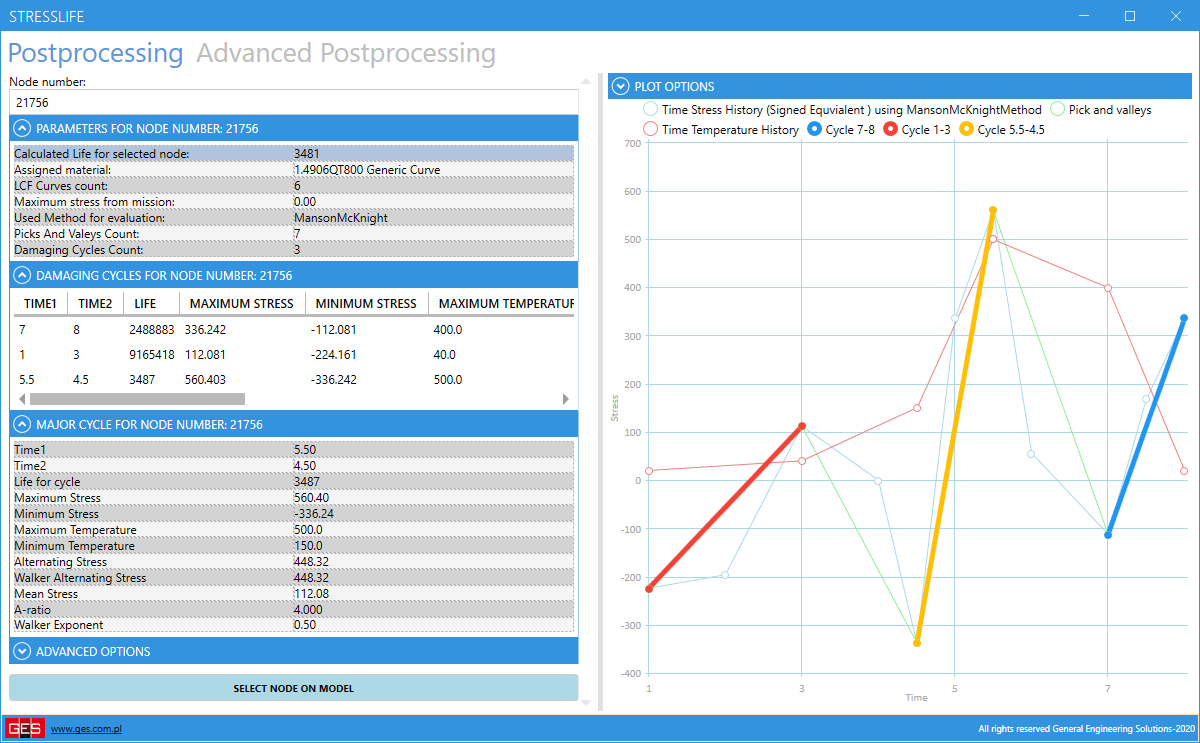

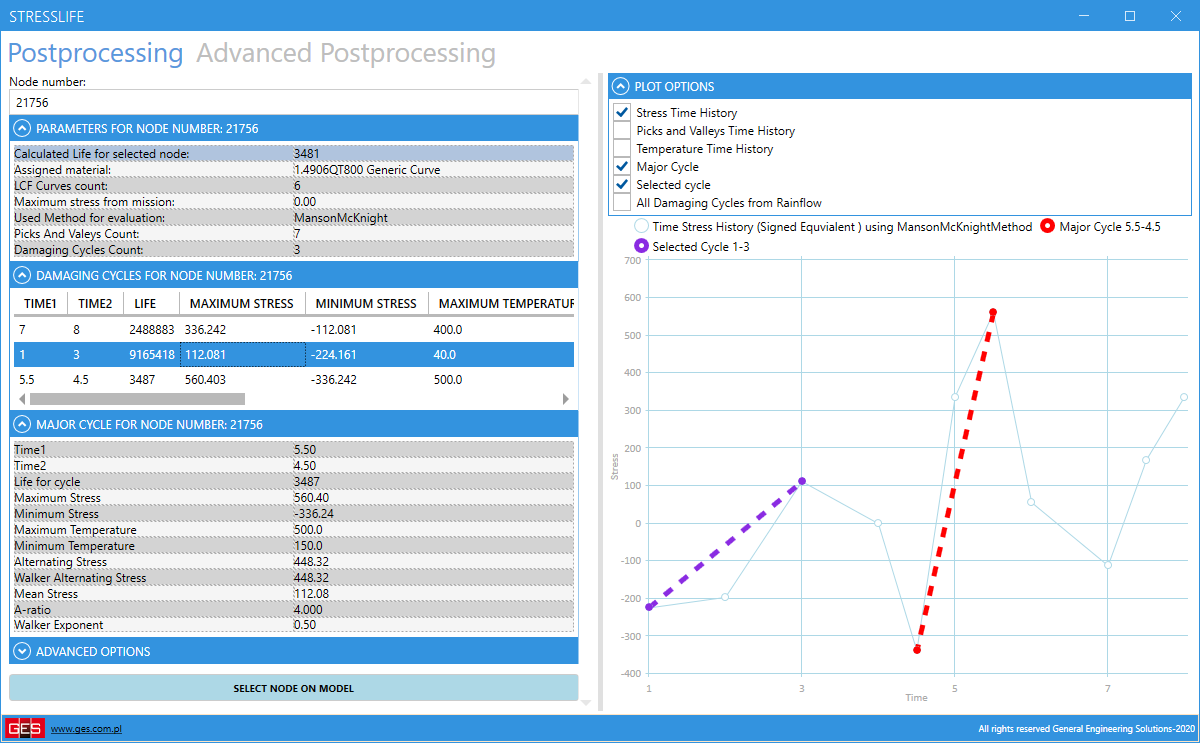

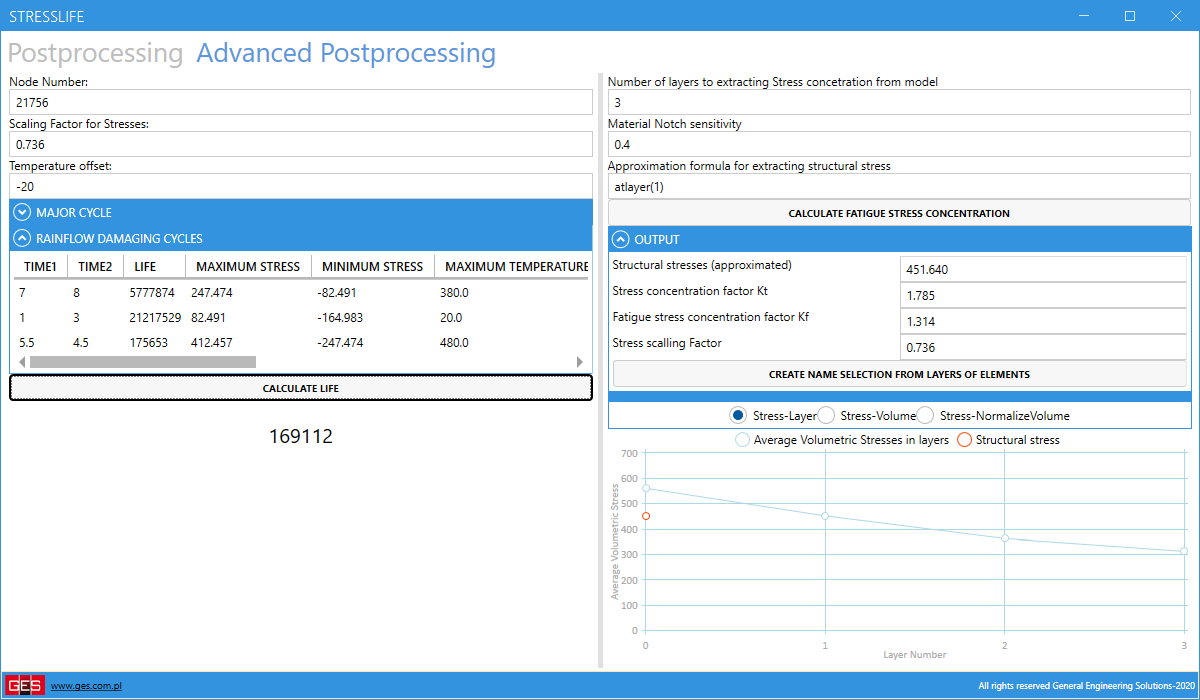

In order to facilitate the analysis of the results, an additional graphical interface was implemented. Thanks to this solution the user is able to display the results in text and graphic form for selected regions in the model. This interface gives the possibility to display such information as:

- node number;

- he calculated life value;

- the method and material

- the method used; and the material used;

- information about the main cycle;

- information of side cycles;

- graphical representation of missions and cycles with additional options.

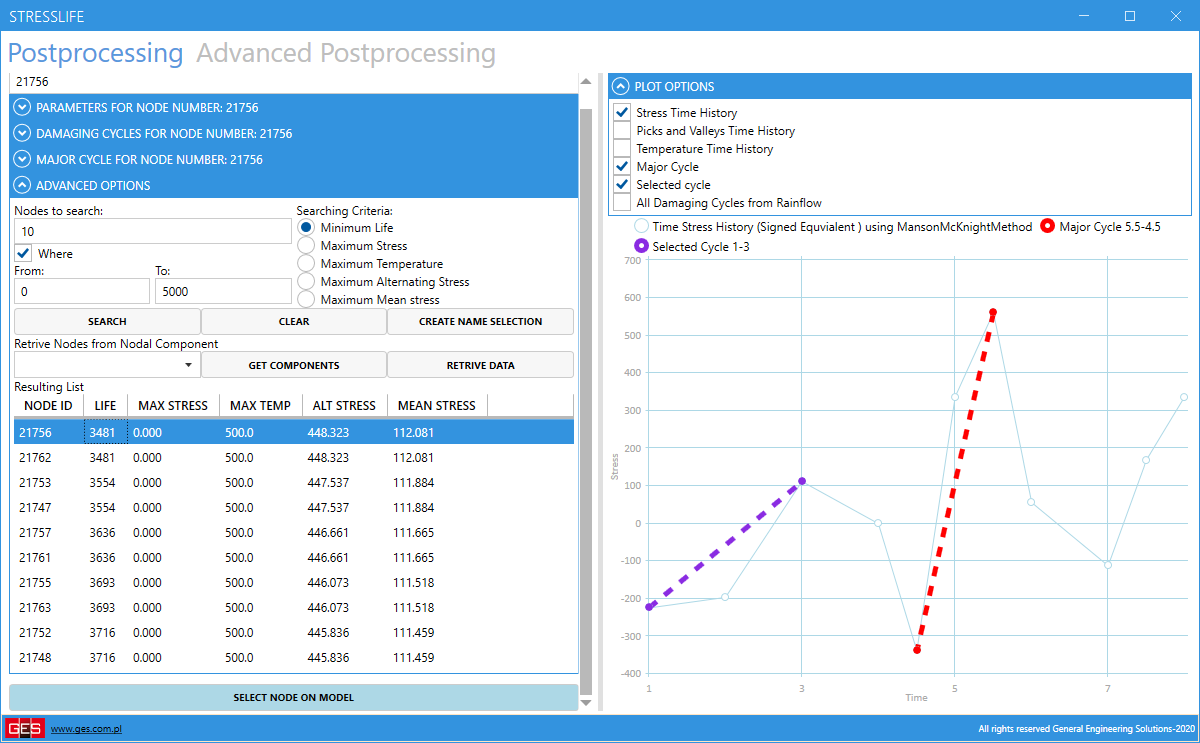

The program automatically finds and indicates the node with the smallest life in the FEM model.

In order to optimize the analysis of the results, the tool has been equipped with additional methods of searching the obtained results on the basis of predefined criteria. It is also possible to create components based on these criteria.

Advanced post processing options for results include:

- consideration of scaling factor and temperature offset for node life calculation;

- calculation of a scaling factor for stress with consideration of the material’s notch sensitivity factor.

Structural unconcentrated stress option

In order to calculate the stress scaling factor, it is required to determine the unconcentrated stress at a given location. For this purpose, stress averaging by volume within a node has been implemented.

To increase the flexibility of the tool, the possibility of defining custom functions for stress averaging at a concentration point has been introduced. The user can choose from several predefined functions such as:

- atlayer(3) – retrieves information about averaged stresses in layers 1-3;

- atfirstlayer() – retrieves stress information for layer 0 – concentrated stresses in a node;

- atlastlayer() – retrieves stress information for all layers;

- sig(value, ‘layer’) – retrieves stress information for distance measured in layers;

- sig(value, ‘volume’) – retrieves stress information for a given volume;

- sig(value, ‘normalize’) – retrieves distance stress information measured in the normalized volume to the total selected volume;

- the approximation follows the relationship below:

The tool also presents the change in stresses across layers and volumes. This allows the user to better understand the stress concentrations in a given region and to select the appropriate platform.

ADVANTAGES AND KEY FUNCTIONALITY:

- fatigue life calculation of parts based on the approach presented in NASALIFE;

- ability to use curves for single and multiple temperatures;

- correction of curves according to the asymmetry factor of the curve cycle;

- logarithmic interpolation of data with linear temperature interpolation for material curves;

- writing and reading data from a file;

- generating material curves from static data;

- searching for hills and lows on mission data for multidimensional stress state using MansonMcKnight and modified MansonMcKnight approaches;

- used cycle counting methodology for repeated missions consistent with ASTM E1049;

- calculations performed for minimum and maximum temperature per cycle;

- damage rainflow – identification of main cycle based on checking all possible combinations of time points from the mission;

- cycle asymmetry consideration using Walker’s method;

- summation of cycles using Miner’s method;

- presenting data in graphical form on the FEM model;

- result processing options include:

- retrieving information for any node;

- automatic search for node with minimum cycle life;

- presentation of results in a user-friendly manner;

- presenting stress history, rise and valley points, temperatures etc;

- presentation of structural failure cycles;

- determination and presentation of main structural failure cycle;

- searching the results for lowest life, highest temperature, highest stress, highest amplitude or average stress;

- reading data for nodes from components and creating components from selected nodes

- consideration of stress scaling factor and temperature offset

- calculating the stress concentration factor for fatigue cylinders;

- calculation of unconcentrated stresses for a given location including volume averaging;

- presenting volume-averaged stresses as a graph as a function of concentration location.

Check our solutions and tell us if we were able to speed up your process.

| Ansys Release | 2019 R3 |

|---|---|

| Target application | Mechanical |

| Analysis type | 3D Static structural |

| Licence type | Paid |

| Period of paid licence | The price quoted relates to the annual licence. |

| Version | V195.0 |