Turbomachinery industry

Since its foundation, General Engineering Solutions have specialised in numerical computations for turbo machine industry. The scope of services provided by us includes strength, thermal, fatigue and advanced flow rate computations. GES ensures comprehensive engineering services adjusted to individual needs of a particular contractor.

Their scope involves all stages of project: detailed analysis of particular components, design, production, tests, research and development.

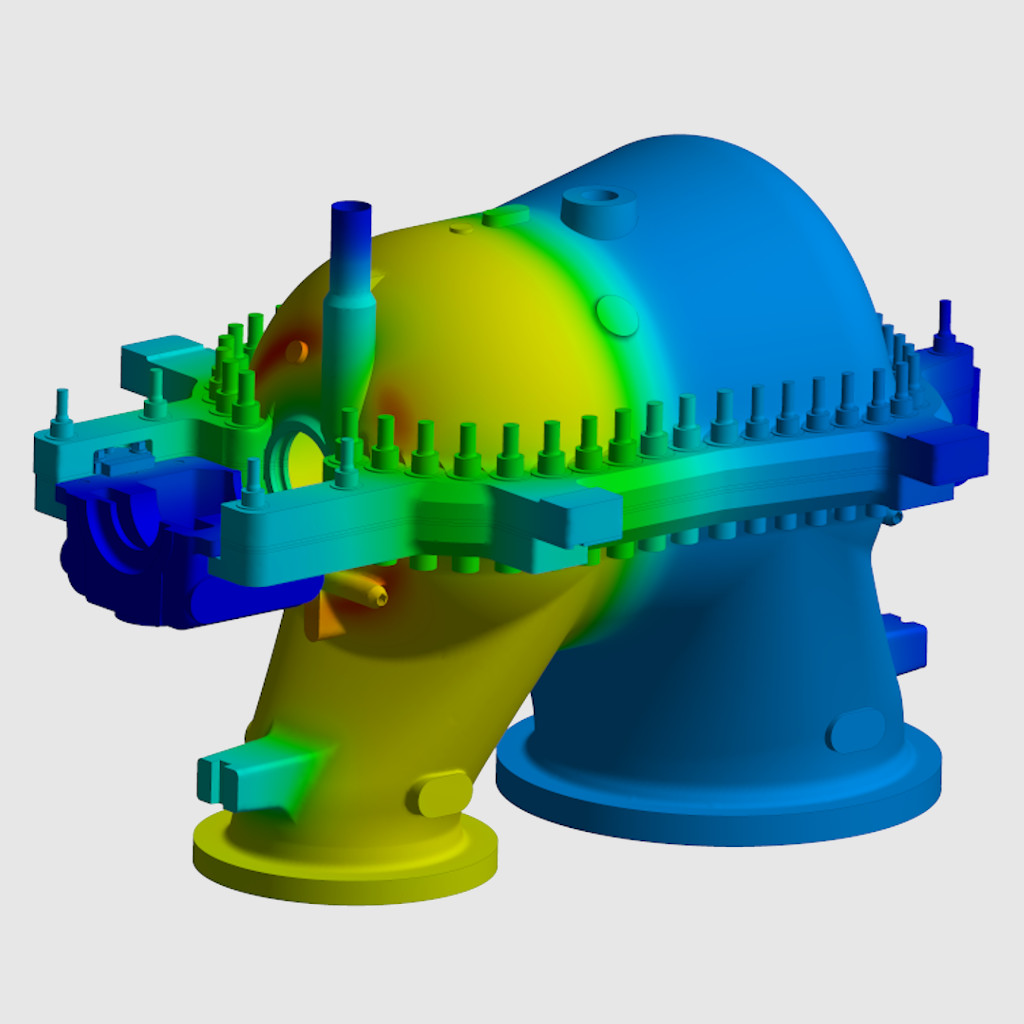

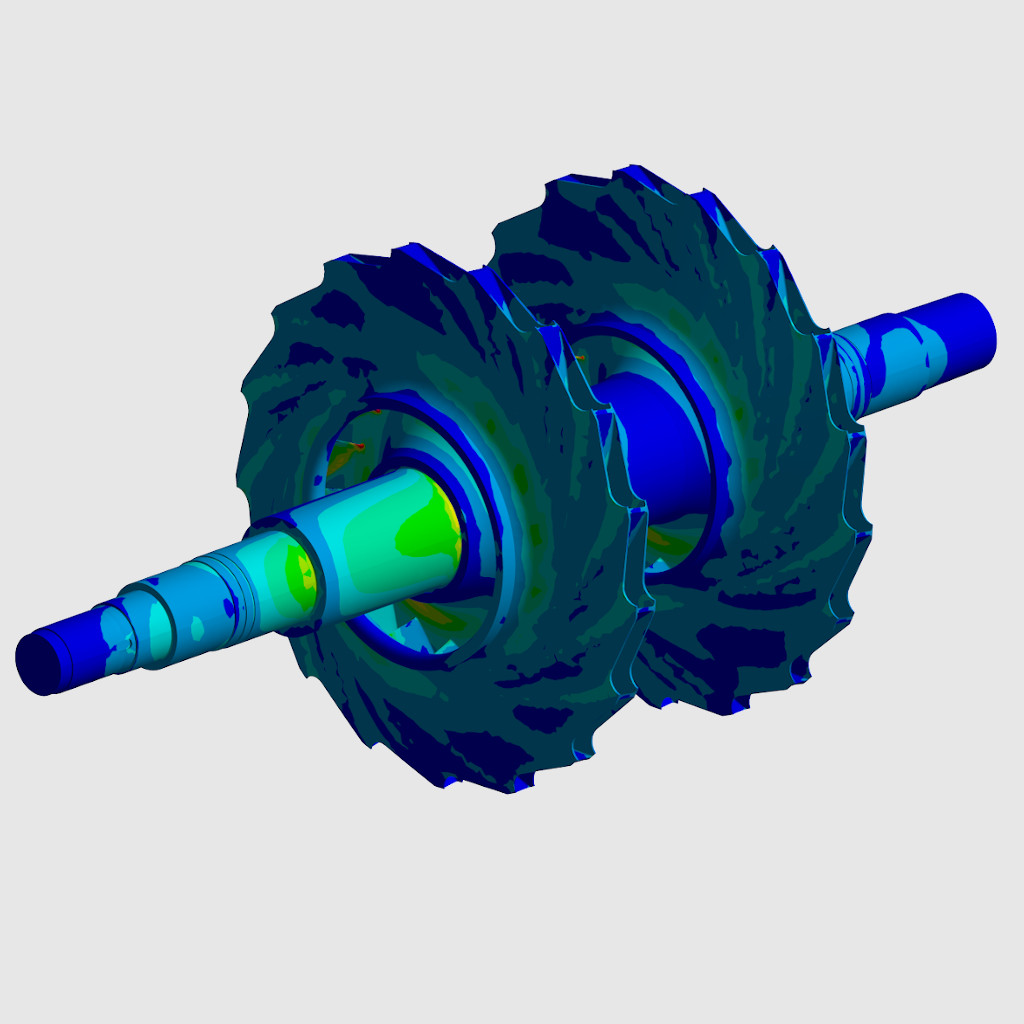

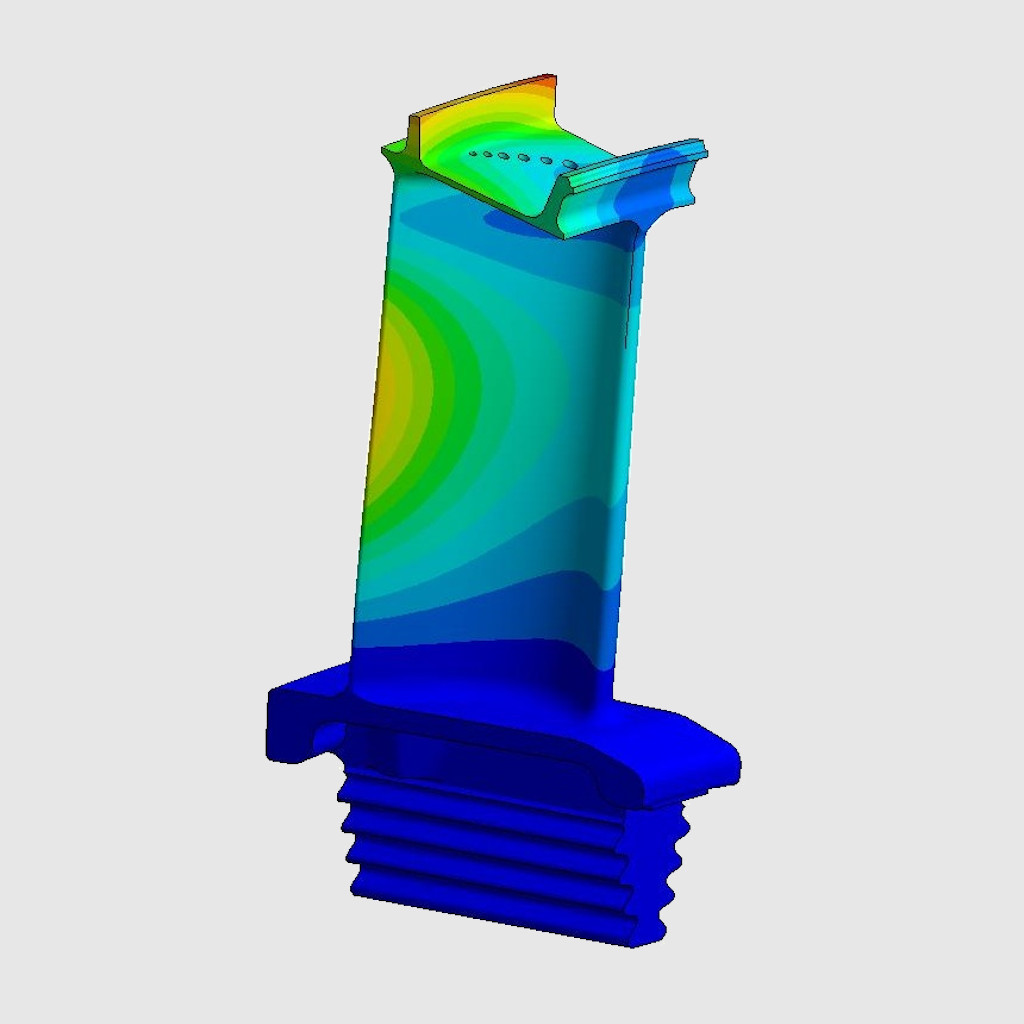

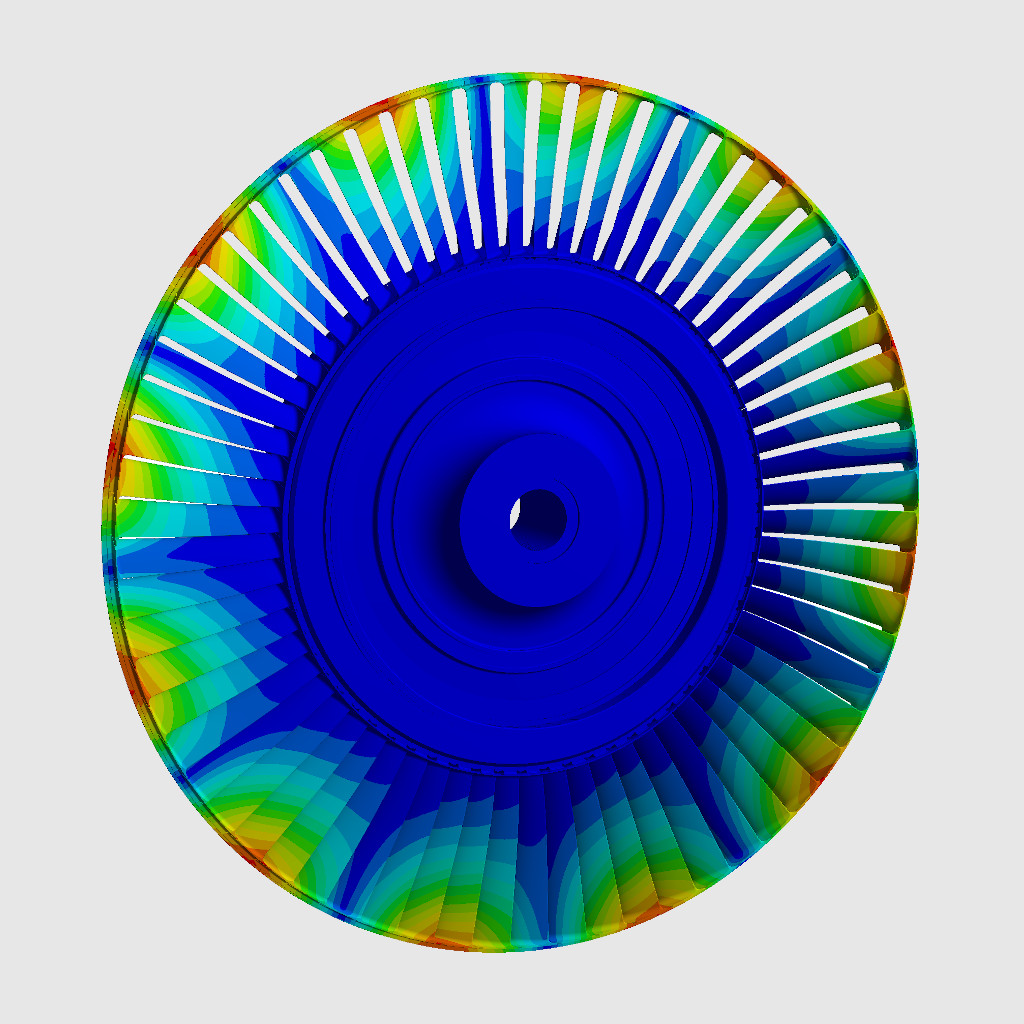

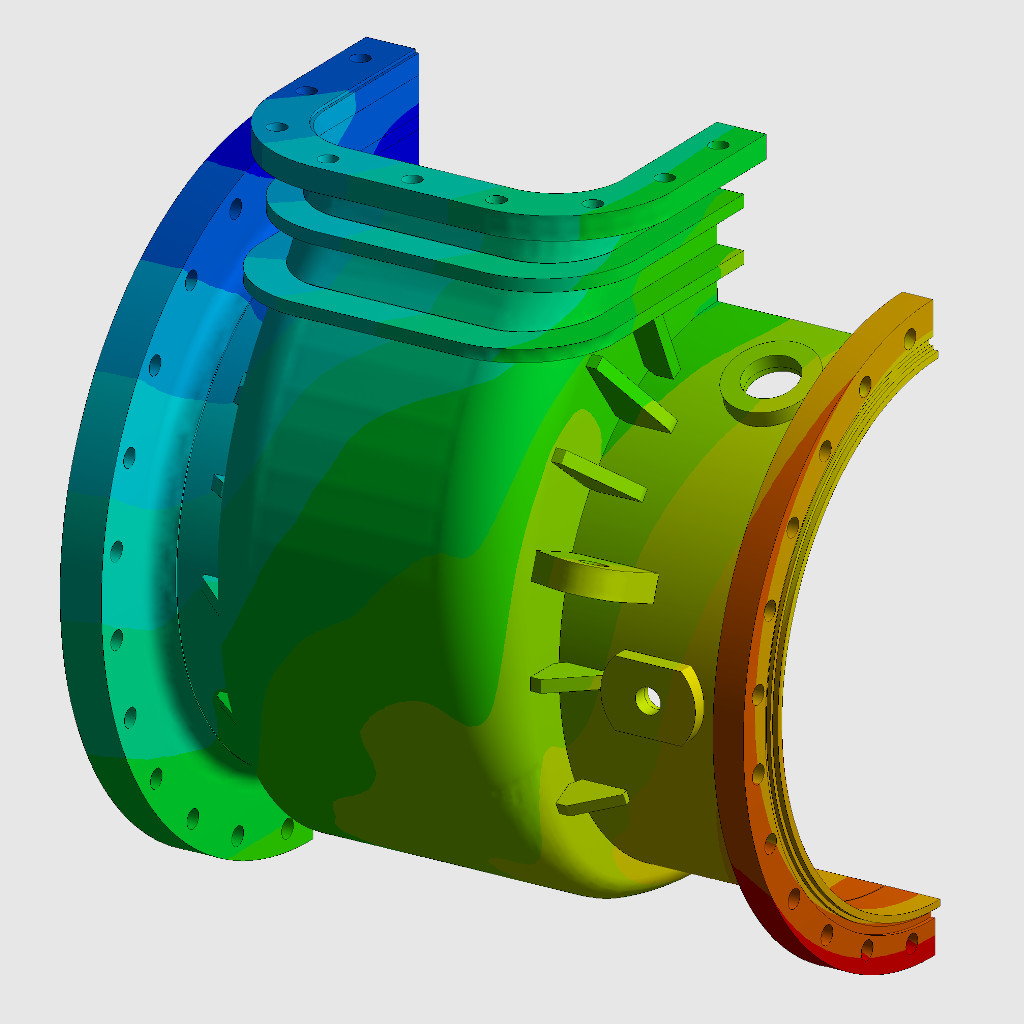

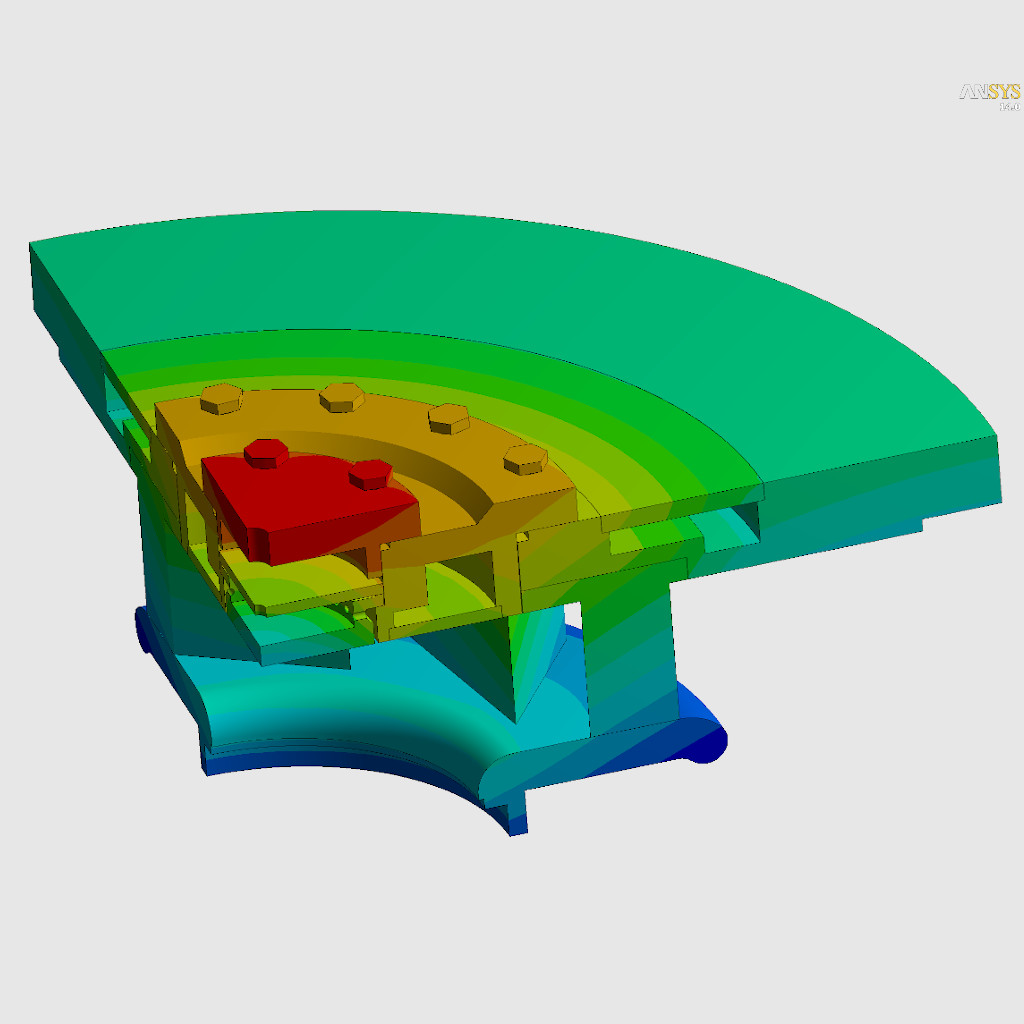

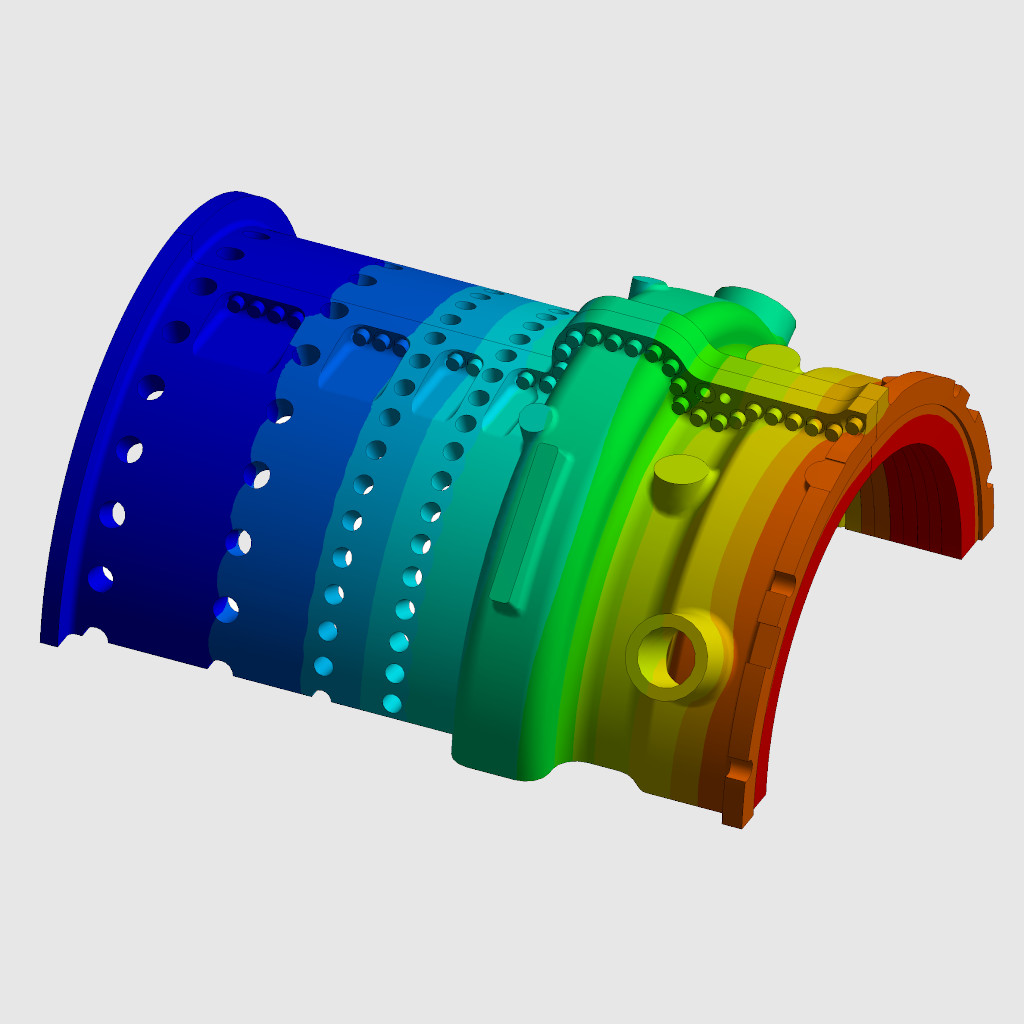

In our daily work we conduct computations of sub-assemblies of gas and steam turbines both for stationary components and rotational high and low pressure sections.

We ensure product support during its whole lifespan.

Projects we carry out include all areas of knowledge of fluid-flow machine engineering, from basic analyses and tests, through design, to combustion chamber analyses. Should such need arise, our engineers are able to work directly in the Client’s office, which enables quicker team communication and problem reaction.

Should you be interested in the services provided, do not hesitate to contact us.

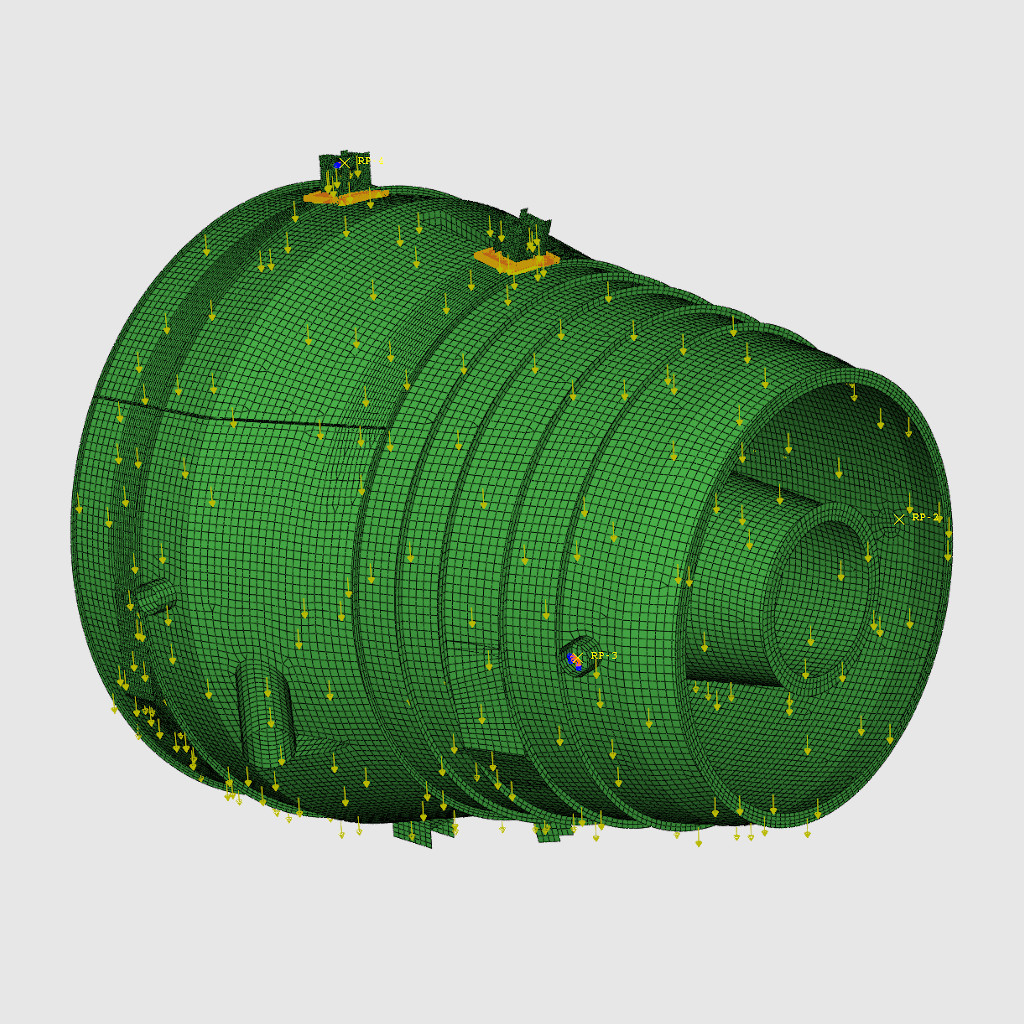

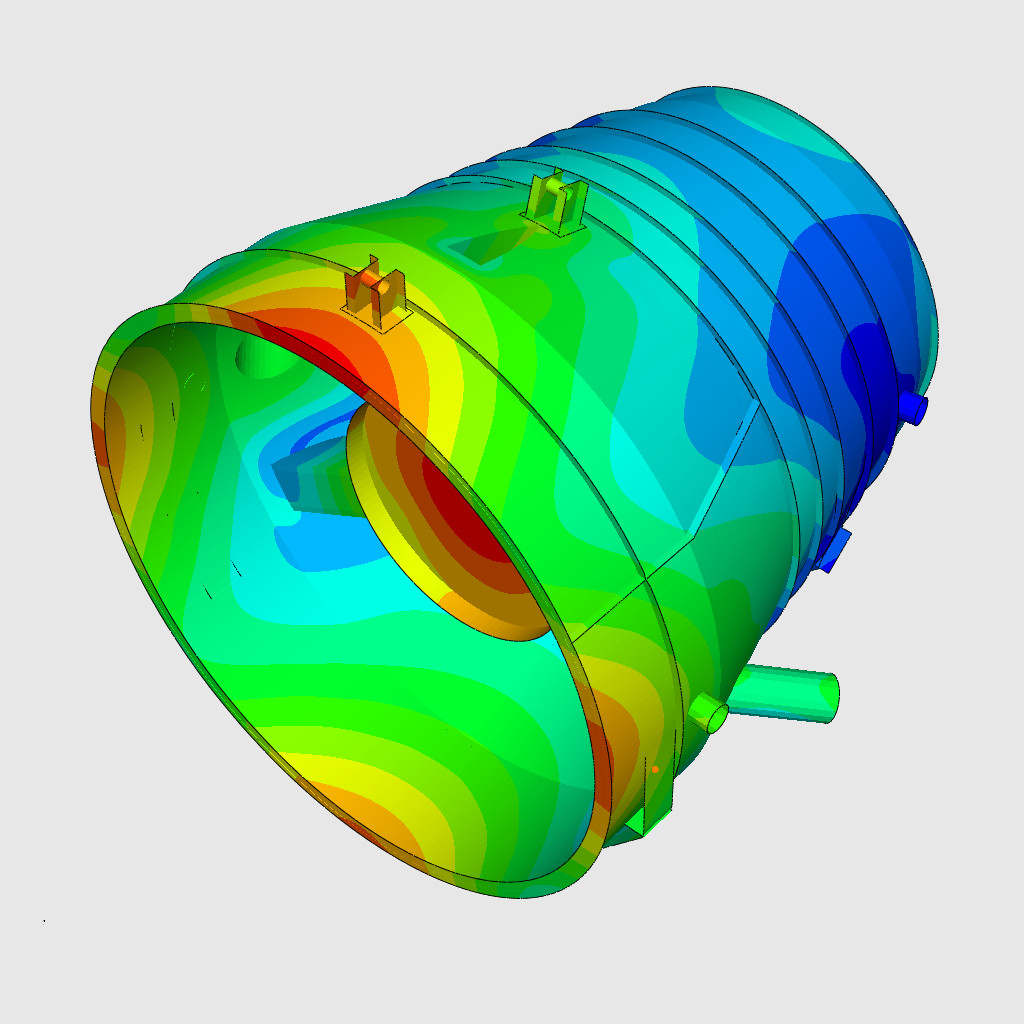

FEM analysis scope

- steady-state and transient strength analyses. The most important projects include:

• strength analysis of the blades in a section of a high-pressure GT

• strength analysis of a compressor shaft

• strength analysis of the disks in a high-pressure GT section

• strength analysis of a combustion chamber and a transition duct - steady-state and transient thermal analyses

- the effect of thermal stress on structures

- harmonic analyses

- modal analyses of blades and complete blade rings, taking in to account thermal stress, the centrifugal force and the forces from the working medium (pre-stress modal analysis) – defining typical forms of deformation and resonance frequencies (Dispersion, Campbell, Goodman diagrams)

- plastic deformation analyses

- high-temperature creep analyses

- analyses of thermal and mechanical deformation between individual components (clearance analysis)

- analyses of flange to flange contact

- analyses of bolt connections to ensure proper contact

- optimization of structures in terms of stress reduction and material selection

Other services for turbomachinery

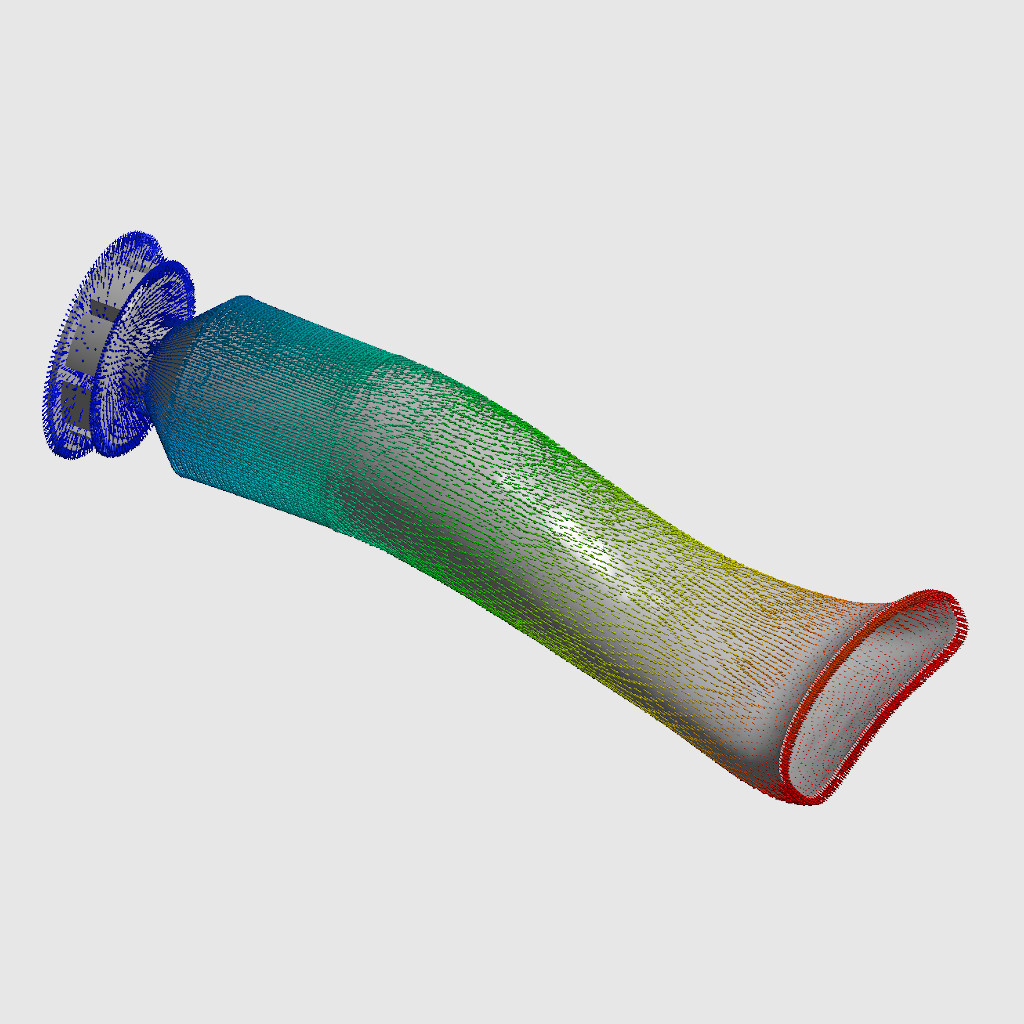

COMBUSTION CHAMBERS

- low emissions combustor design-dual fuel

- bio-fuel burner design, High H2 and CO content fuels

- redesign/retrofit low emissions burner

- GT transition duct redesign for life extension

- auditing of GT combustor development

- multi-fuel nozzle system design for syngas, diesel, LPG operation

- high pressure rig testing-use of Design of Experiments techniques

- fatigue and life assessment

- steady-state and transient strength analyses

- steady-state and transient CFD flow analyses, taking in to account chemical processes and heat exchange optimization of structures to ensure the maximum lifetimes of components

- optimization and adaptation of systems for the use of alternative fuels

- optimization of materials

PROJECT MENAGMENT

- project management to cover the control of the engineering work

- liaison with manufacturing

- 6-sigma approach to problem definition and solving

INSTRUMENTATION & CONTROLS

- turn key solutions tailored to specific needs

- monitoring system

- strain gauge

- specialist temperature probes

- emissions probes

- robust, reliable control systems for long term use (thousands of hours)

- optical probes (spectrometers & fast acting flame detectors)

- high temperature & pressure endoscopes

- vibration monitoring/diagnostics and flow instability detection